With over 30 years of proven experience, Husky makes specialty closure molds that deliver industry-leading reliability and part quality with an unmatched level of precision. THE TURNKEY SOLUTION Specialty Closure Molds To comply with the upcoming European Directive, Husky is developing a portfolio of innovative tethering solutions that prioritize the consumer experience without compromising performance or weight. Our portfolio is available in a wide variety of resin and master-batch combinations to meet OEM levels of performance. Our dynamic portfolio of closure options are compatible with industry standard neck sizes for the water, carbonated soft drink (CSD) and sensitive (JSDT) markets.

#PET PREFORM MOULD FREE#

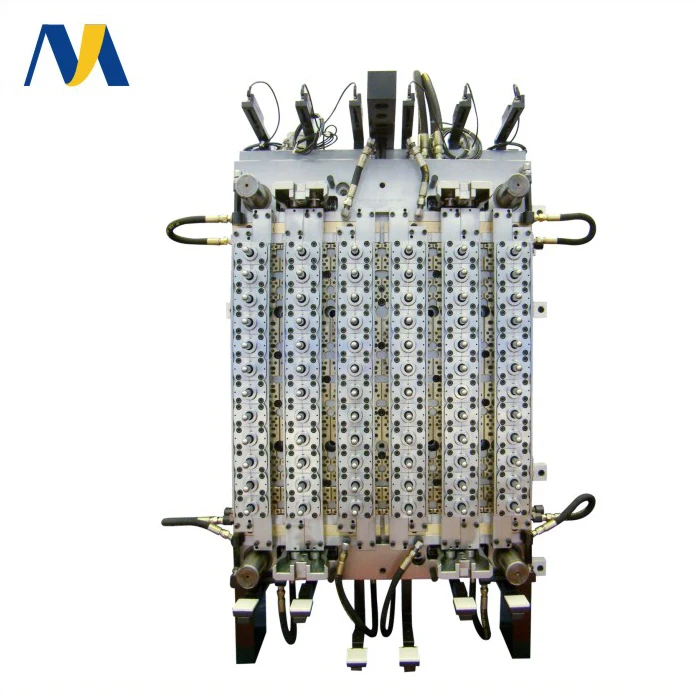

Innovative features like free motion slides eliminate the need for horn pins and photo eyes, thereby improving cycle performance and avoiding the risk of mold collisions. These molds are an integral part of our advanced H圜AP TM4 injection molding system. Husky is your partner for the long haul.įor high-speed performance, robustness and quality, nothing outperforms H圜AP TM closure molds. And we will work with you to make certain you have the right PET preform injection molding system-including machine, mold and auxiliaries-for your current and future needs. They’ll dependably process virgin PET or rPET flake and pellets to bring greater sustainability to your end products.

Whether you need new PET preform molds, restoration or refurbishment, or conversion of your existing tooling to our state-of-the-art technologies, Husky has your injection molding solution. As the world’s largest preform mold maker, Husky brings you unparalleled productivity with the highest-capacity injection molds and systems in the business.

0 kommentar(er)

0 kommentar(er)